MAKE IT REAL

For over 25 years I have the privilege to design and develop a broad variety of projects.

SAFETY PRODUCTS

Child safety seats Beyond @ HTS BeSafe

Design and engineering of BeSafe Stretch in the NPD team.

I was involded during engineering in this project.

-plastic injection moulding

-Aluminium

Development process:

- engineering parts and assemblies

- optimization

- extensive crash tests (international)

Stretch @ HTS BeSafe

Design and engineering of BeSafe Stretch in the NPD team.

Kind&Jugend Sustainability award 2023 nominee

-plastic injection moulding

-Aluminium

Development process:

- engineering parts and assemblies

- optimization

- implementation in production

- extensive crash tests (international)

BeSafe Stretch B

The BeSafe Stretch B is totally developed from a sustainability perspective, according the principles of the so called 'value hill'. The lifespan is expanded to 15 years, where most carseats have a max. lifetime of 7-8 years. This is done by using durable materials like Aluminium which is not subject to corrosion and EPP, which is a very tough and durable foam type. The product is developed to get repairs for parts which can wear and can be refurbished after a usage period of 7 years to get it secured and fresh again for a second usage period. Where possible recycled materials are used, for example for the polyester fabrics. When the product is at the end of its lifespan, the product can be disassembled and different materials can be recycled.

Child safety seats @ HTS BeSafe

Design and engineering of iZi Twist / Turn in the NPD team.

-plastic injection moulding

-steel deforming

-2K overmoulding

Development process:

- engineering parts and assemblies

- optimization

- implementation in production (international)

- extensive crash tests (international)

Child safety seats @ HTS BeSafe

Design and engineering of iZi Modular in the NPD team.

-plastic injection moulding

-steel deforming

-2K overmoulding

Development process:

- engineering parts and assemblies

- optimization

- implementation in production (international)

- extensive crash tests (international)

SUSTAINABLE ENERGY

Solar doorbell for Econcern @ Betronic

Design and engineering of a sustainable doorbell, powered by solar energy.

Including aluminium casting, injection moulding, PCB integration.

From sketch to production, including production start and quality documents.

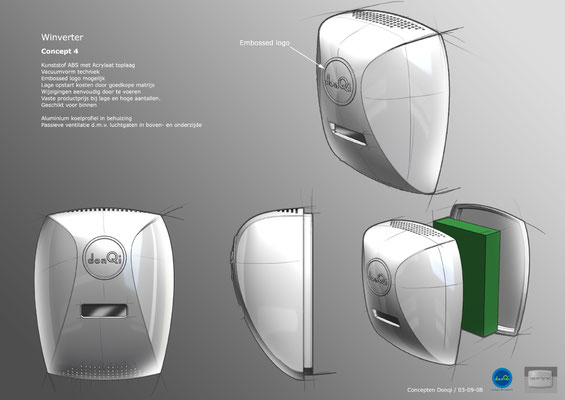

Inverter for wind energy for DonQi @ Betronic

Design and engineering of an inverter for wind energy.

Including aluminium casting, injection moulding, PCB integration, IP 65.

From sketch to production, including production start and quality documents.

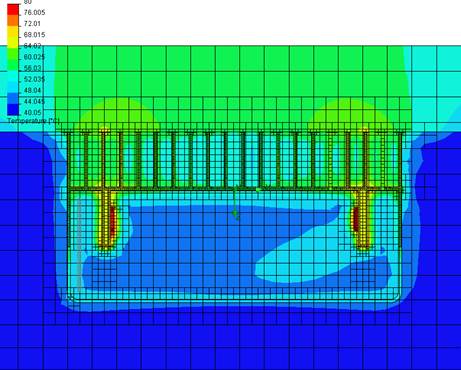

Converter for solar energy for Femtogrid @ Betronic

Development of a converter for solar energy.

Including aluminium extrusion, integration and optimisation of electronics.

Use of Solidworks Flow simulation program for virtual optimisation.

Solar hub @ Betronic

Development of a converter for solar energy.

Including aluminium extrusion, integration and optimisation of electronics.

Use of Solidworks Flow simulation program for virtual optimisation.

ELECTRIC MOBILITY

Complete electronic bike range for Koninklijke Gazelle @ Betronic

Development, design and engineering of 3 different electronic bikes.

Cable integration, plastic enclosure development and styling, rotation sensor development.

From sketch to production, including PCB, hardware and software integration.

Electronic bike display for TDR @ Betronic

Development, design and engineering of electronic bikes.

Cable integration, plastic enclosure development and styling.

From sketch to production, including PCB, hardware and software integration.

Signs and displays

Signs and displays

Signs and displays / international customers @API NEON

Development, design and engineering.

Including sourcing China and sales support through Europe.

Display for Nintendo / Thermoformed with steel support

Sign for Levi's Europe, including aluminium extrusion, silk screen printing

House hold appliances

House hold appliances @Tristar Europe BV

Development, design and engineering of products and packaging.

Including sourcing Turkey and sales support through Europe.

Coolbox.